About Us:

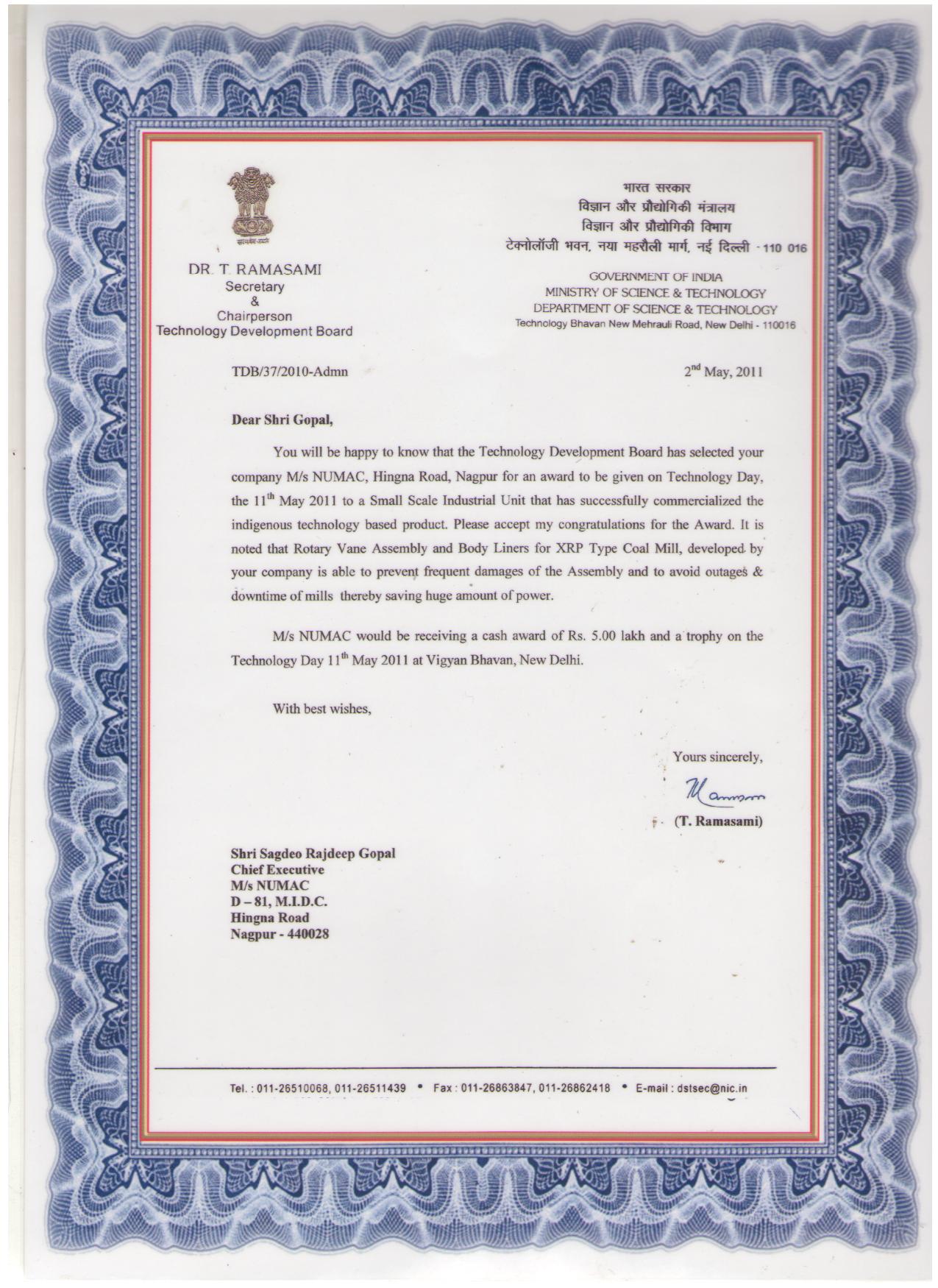

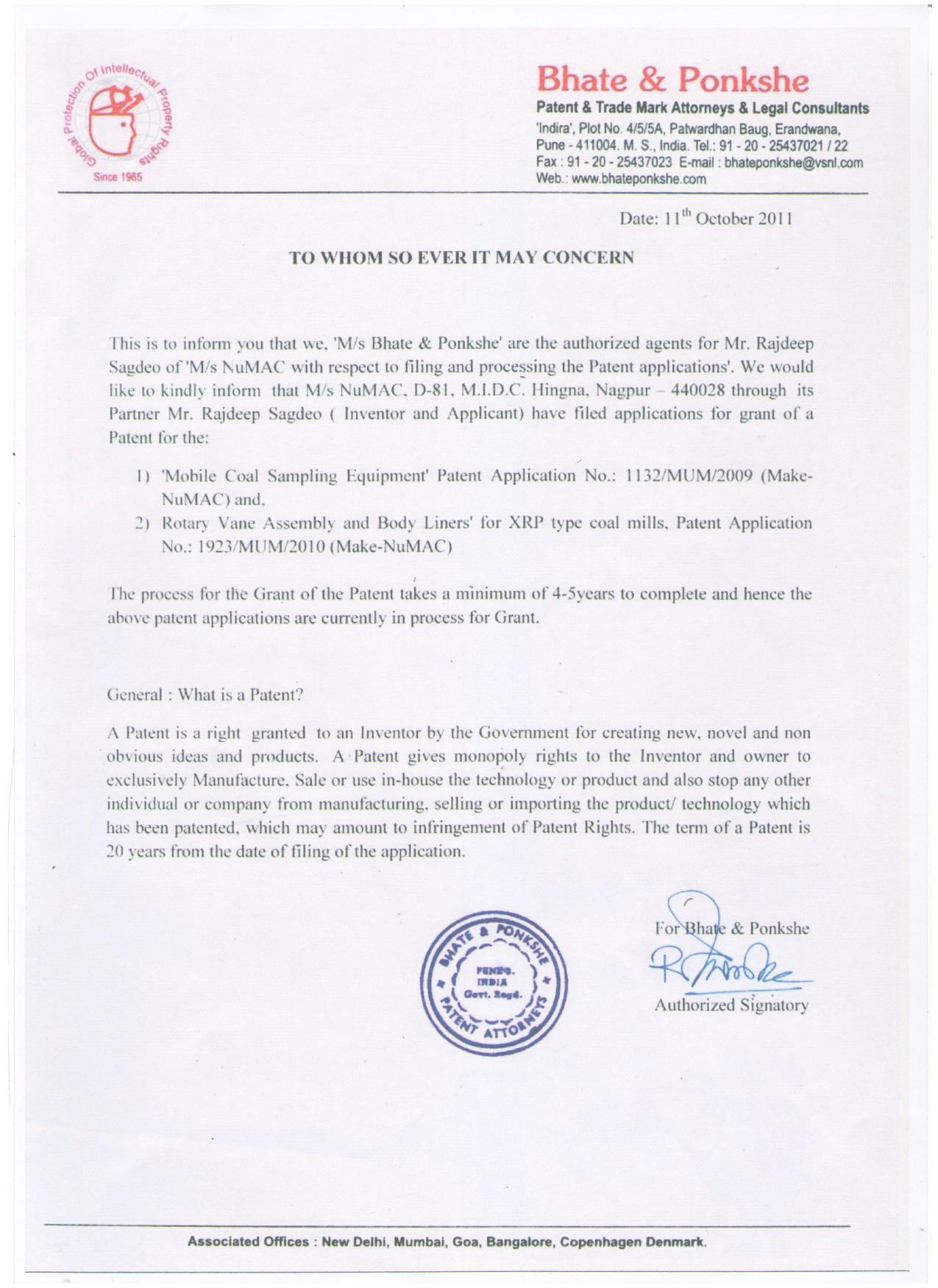

(M/S NuMAC, Nagpur receiving the national award for “Rotary Vane Assembly & Body Liners” and “Mobile Coal Sampling Equipment” at the hands of Dr. A.P.J Abdul Kalam on The Technology Day, 11th May 2011, The Technology Day, at Vigyan Bhawan, New Delhi.)

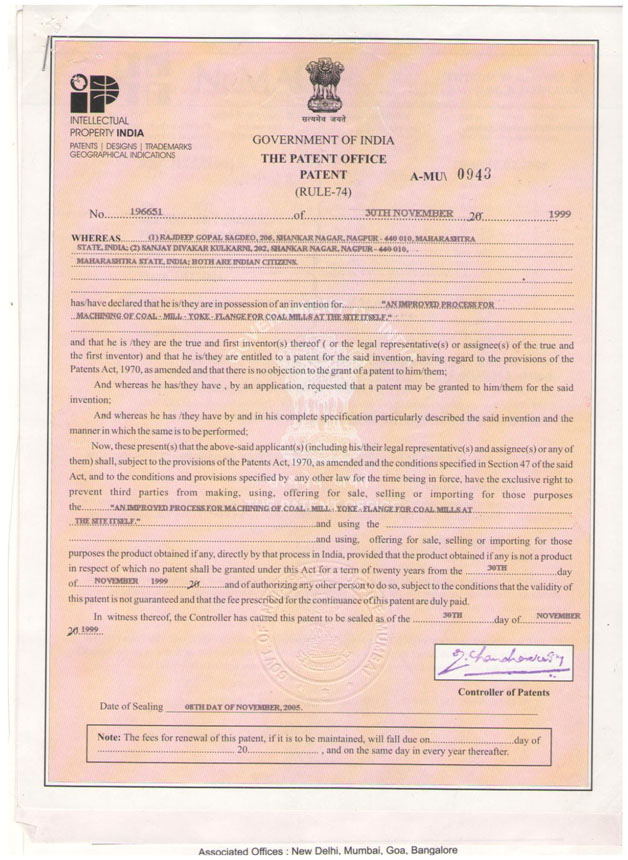

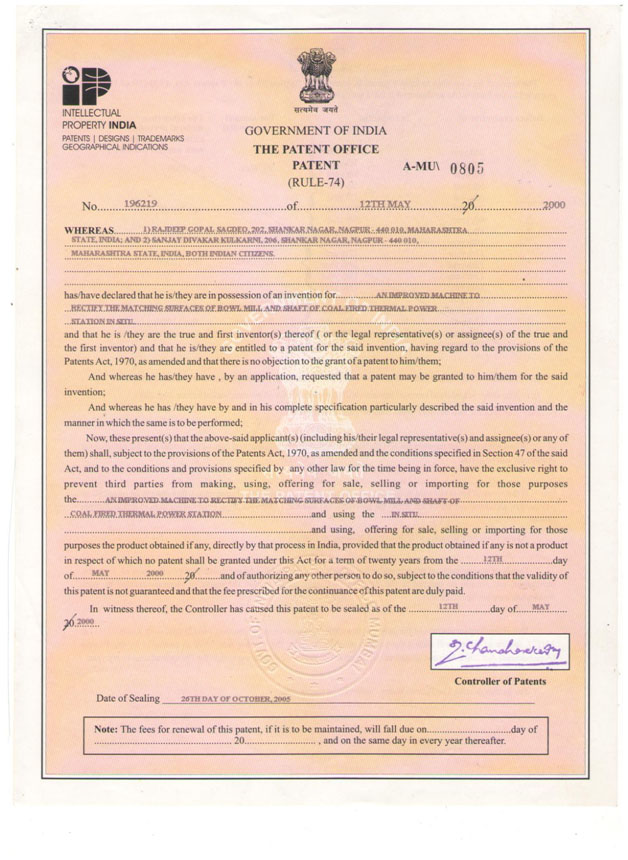

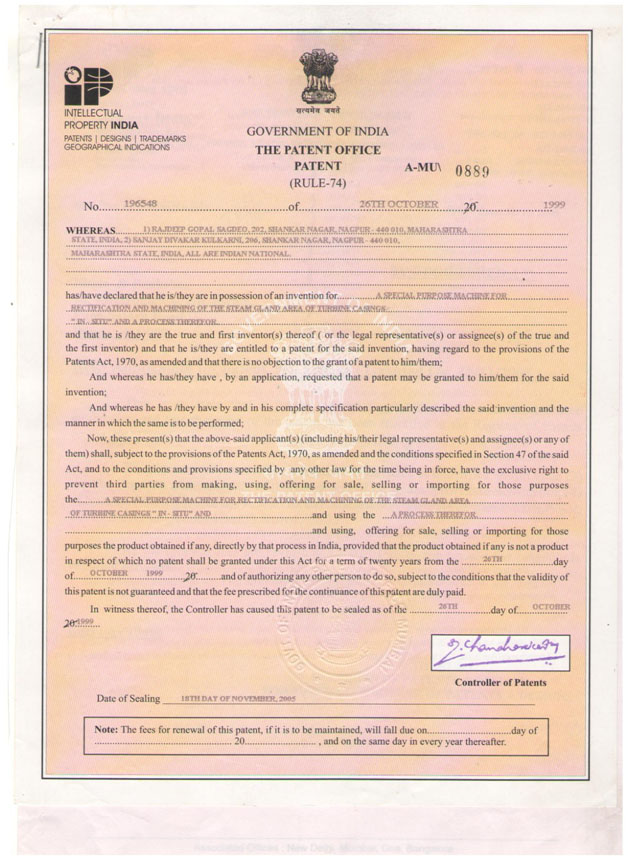

As stated earlier NUMAC, has been specialized in Manufacturing of Mobile Coal Sampling Equipment, Rotary Vane Assembly, Dynamic Balancing, Heavy engineering, rebuilding and reconditioning of machines, Industrial Fabrications, Polymer coatings, manufacturing of Special Purpose Machines, Import substitute items and precision parts are some of the executed jobs which isolates NUMAC in real sense. We have manufactured import substitute parts like Wiper Rings, pump shafts, sealing rings, CEP spares, valve spares, air seals, labyrinth, gland box, repairs like coal mill parts, shafts, impellers, fans, yoke flanges, spider rings etc. following are the works done at NUMAC.